Atmospheric Water Generator

Creating pure water from the air is no longer a far-fetched idea confined to science fiction. Thanks to the development of atmospheric water generators, this technology is now available for home use. Just imagine the convenience and benefits of producing pure drinking water that is not only healthy but also environmentally friendly and surprisingly affordable. The potential of tapping into the vast water resources in our atmosphere holds great promise for addressing the growing concern of water shortages worldwide.

The Ultimate Water For Health is From an Atmospheric Water Generator

One of the most significant advantages of atmospheric water generators is their positive impact on the environment. As environmentally conscious individuals, we are well aware of the detrimental consequences of bottled water. Not only does it often come at a high cost compared to tap water, but it also leads to excessive plastic waste that pollutes our planet. Communities are increasingly recognizing this problem and taking steps to ban bottled water from their buildings and events. By utilizing atmospheric water generators, we can actively contribute to averting water shortages during crises while simultaneously reducing recycling costs and water container pollution in our communities. Choosing to generate our own water empowers us to protect the environment without making sacrifices.

Another compelling aspect of atmospheric water generators is their financial viability. While the concept of extracting water from the air may sound futuristic, the technology behind it is not entirely new. This has led to the availability of these generators from various companies, which is good news for consumers interested in purchasing them. The competition in the market has driven down prices considerably, making atmospheric water generators a cost-effective option. By investing in a unit, we can enjoy the benefits of drinking clean and healthy water without straining our wallets. In fact, the overall cost can be comparable to buying a cooler dispenser and heavy bottles of uncertain quality water. Additionally, the convenience and savings from not having to purchase individual water bottles can further contribute to reducing our expenses.

The urgency of the world's dwindling fresh water supplies cannot be ignored. While some may remain uninformed about this critical issue, lack of knowledge does not make the problem disappear. It is important to recognize that the reality of water scarcity is looming like a tidal wave, and its impact will be felt globally in the coming years. The current state of billions of people lacking access to clean drinking water should serve as a wake-up call. Regardless of whether we personally experience immediate distress or urgency in our own areas, the severity of the problem demands our attention. We must not allow ourselves to be complacent or swayed by distractions. The mainstream media, unfortunately, often fails to provide comprehensive and unbiased reporting on important issues, further contributing to public unawareness. Taking proactive measures to secure clean water sources is essential to safeguarding our future.

Only 3% of the world's water is fresh water, with a significant portion of it locked in polar ice caps. Unfortunately, the effects of climate change and global warming are causing this precious resource to transform into salt water as it melts and merges with the oceans. Disturbances in rainfall patterns, readily observable signs of climate change, are already impacting fresh water supplies. The ever-increasing population growth, expanding agriculture, and intensifying manufacturing processes necessary to support growing populations are placing immense stress on our already limited fresh water resources. Even if water is currently available where we live, the quality of that water is rapidly deteriorating due to pollution and contamination. The infiltration of substances such as oil, chemical runoff, nitrates, sewage, and fertilizers into our water supplies not only leads to shortages but also makes the available water unfit for consumption. The alarming consequences of neglect, misuse, and carelessness regarding existing water supplies highlight the urgent need for sustainable solutions.

Scientists Have Created a Device That Sucks Water Out of Thin Air, Even in the Desert:

Official documentation: 👉 Water Liberty Guide was born

✔ It’s the only proven, EXCLUSIVE step-by-step guide showing you EXACTLY how to create your own “home oasis” TODAY…and how to survive any tough century long drought…

✔ It was providing a steady, robust supply of fresh, pure water ON DEMAND…

Related document: Free Electricity and Water SolutionsSelection of the best Atmospheric Water Generator on the market

In a world facing increasing water shortages and environmental challenges, atmospheric water generators emerge as a groundbreaking solution. These innovative devices have the power to avert water crises, reduce recycling costs, and combat water container pollution in communities. By harnessing the oceans of fresh water present in our atmosphere, atmospheric water generators offer a sustainable way to ensure access to clean drinking water without sacrificing the environment.

While the idea of extracting water from the air may seem futuristic, the technology behind atmospheric water generators is rooted in older principles. As a result, several companies now provide these generators, making them readily available to consumers. The competitive market has significantly driven down the prices, enabling individuals to save money by investing in their own unit. By opting for an atmospheric water generator, you can enjoy the ultimate water for health at a cost comparable to purchasing a cooler dispenser and heavy bottles of water, without the need for single-use plastic bottles. Furthermore, the convenience and affordability of these generators make them a more practical and sustainable alternative to buying individual water bottles, offering potential savings on your water bill while promoting environmental responsibility.

1/ Airiver 5-in-1 Atmospheric Water Generator, Water Freedom System - No Plumbing or Piping - 30L/Day - Light Alkaline, Ionized, Mineralized Water, Dehumidifier, and RO in One - Hot/Cold Dispenser

COMPLETE CONTROL OVER YOUR WATER SUPPLY: Never worry again about the cleanliness or security of your water with this air-to-water generator that transforms humidity from the air into pure, clean water in 24 hours using standard electricity, activated carbon filters and a reverse osmosis membrane filtration system that removes impurities.

PUREST WATER YOU’VE EVER TASTED: The key to the best tasting water on the planet is our osmosis filtration system, which uses a membrane filter to keep out contaminants and three, carbon filters that block unpleasant elements and odors, so only clean and purified water passes through.

2/ NUBE: Atmospheric Water Generator 8 gal/day - Alkaline + Ionized + Mineralized- Fluoride and Chlorine Free - Sustainable - Carbon + Osmosis Filter - UV - Cooler/Heater Dispenser - Dehumidifier (White)

★ GENERATE THE PUREST WATER IN THE WORLD! ★ — (Minimum Humidity needed is 35%) You just need air and electric power to produce up to 30 liters per day . No city water supply needed! Gus review is misinformed.

★ 100% HEALTY ★ — Alkaline, ionized, mineralized water, free of chlorine and fluoride

3/ DewStand Series B Atmospheric Water Generator (Model DSB-1F)

Check: 👉 Atmospheric Water Generator - DewStand Series B Atmospheric Water Generator (Model DSB-1F)

4/ DewStand Series A midsize Atmospheric Water Generator Model DSA-1M

Check: 👉 Atmospheric Water Generator - DewStand Series A midsize Atmospheric Water Generator Model DSA-1M

5/ Home 50L/D Pure Atmospheric Air to Water Treatment Dispenser Generator with Intelligent RO Filter NFC Code-Scanning Match Tech

practical use: The simple appearance of this portable fan is perfect for use in home, business and leisure. It can be used as a practical accessory. High temperature resistance, small size and practical.

durability: High quality pc material, sturdy and durable.

premium: The ipad air purifier is made of premium material and has a beautiful design.

Check: 👉 Home 50L/D Pure Atmospheric Air

6/ Home 20L/D Pure Atmospheric Air to Water Treatment Dispenser Generator with Intelligent RO Filter NFC Code-Scanning Match Tech

7/ Popular Atmospheric water generator 50L/day New eco-friendly IOT appliance fresh safe drinking solution

Model | G50s | Capacity | 50L/DAY ( @ 80%RH and 30℃) |

Brand | FND | Water Function | Ambient water or Cold water |

Filter system | PP+ 400G RO + MF+CU(RO filtration) | Place of Product | Guangdong Province,China |

Rated voltage/Frequency | 220V/50HZ, 220V/60HZ, 120V/60HZ | Operation temperature and humidity | 15℃~43℃ >25% RH |

Water Making Power | 880W | Water Tank volume | 19L or 38L |

Scientists Have Created a Device That Sucks Water Out of Thin Air, Even in the Desert:

✔ It’s the only proven, EXCLUSIVE step-by-step guide showing you EXACTLY how to create your own “home oasis” TODAY…and how to survive any tough century long drought…

✔ It was providing a steady, robust supply of fresh, pure water ON DEMAND…

★ Use free electricity for the atmospheric water generator: Free Electricity and Water SolutionsAtmospheric water generator project: SYSTEM AND METHOD FOR PRODUCING WATER

BRIEF DESCRIPTION OF THE DRAWINGS:

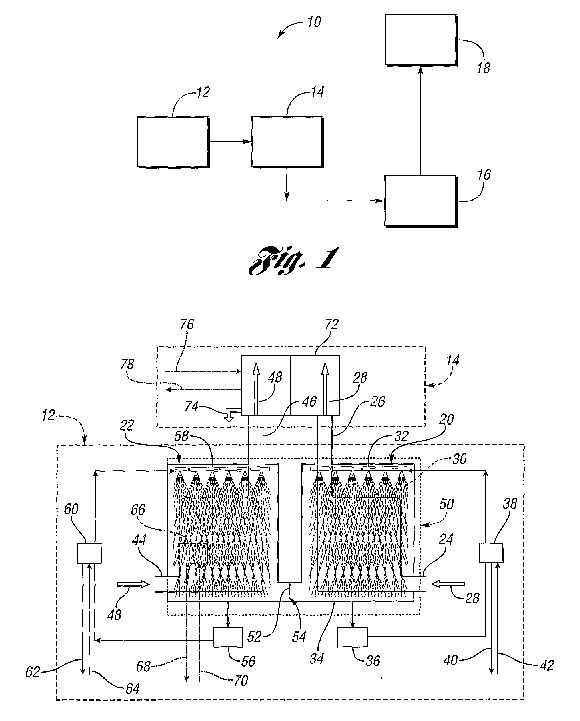

FIG. 1 is a simplified schematic representation of a water producing system in accordance with the present invention;

FIG. 2 is a schematic drawing showing a portion of the system shown in FIG. 1; and

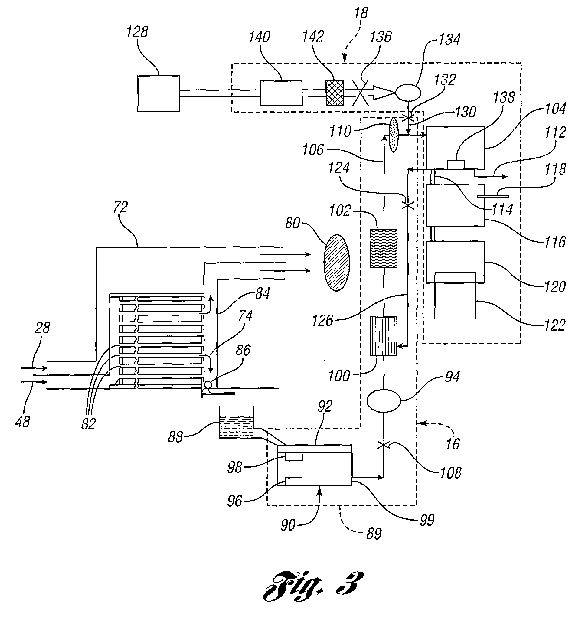

FIG. 3 is a schematic drawing showing another portion of the system shown in FIG. 1.

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT(S)

[0024] FIG. 1 shows a simplified schematic diagram of a water producing system 10 in accordance with one embodiment of the present invention. The system 10 includes a humid air manufacturing stage 12, a water extraction stage 14, a water purification and filtration stage 16, and a water dispensing stage 18. As described in more detail below, the humid air manufacturing stage 12 includes processes for removing moisture from an ambient air mass, and transferring it into another air mass by use of a desiccant material. The moisture collected in the desiccant material is evaporated into the second air mass, which results in the generation of warmer air with higher humidity than the initial ambient air.

[0025] The water extraction stage 14 includes a heat exchanger or absorber that cools the humid air stream manufactured in stage 12. The air stream is cooled to its dew point, thereby resulting in condensation of water vapor and production of liquid water. The condensed liquid water may be filtered and/or otherwise purified at stage 16 by any number of purification and/or filtration devices. Such devices may include a bacteriostat loop which serves to destroy adventitious living organisms, and filters which filter out undesirable contaminants. Filtration and/or purification systems used in stage 16 can be configured to reduce contaminants and VOC's to a level defined by National Science Foundation (NSF) Standard 53. A recirculation loop may also be provided to recirculate stored condensate during periods of inactivity.

Related: EXTRACTING WATER FROM AIR

[0026] The water dispensing stage 18 can include a plurality of storage tank systems to dispense water through spigots. Various components in the water dispensing stage can include quick-disconnect fittings to facilitate easy assembly and reconfiguration. Flexible tubing can also be used so that the water can be remotely dispensed, and so that a secondary water source, such as a municipal water supply, can be incorporated into the system 10.

[0027] FIG. 2 shows the humid air manufacturing stage 12 and the water extraction stage 14 in detail. In the embodiment shown in FIG. 2, the humid air manufacturing stage 12 includes a first chamber, or collection chamber 20, and a second chamber, or regeneration chamber 22. The collection chamber 20 includes an inlet 24 and an outlet 26 which allow a first airflow 28 to flow through the collection chamber 20. As the air flows through the collection chamber 20, it is subjected to a first process which includes exposing it to a desiccant 30, which, in the embodiment shown in FIG. 2, is a liquid. The liquid desiccant 30 is sprayed into the first chamber 20 via a conduit 32.

[0028] As the first airflow 28 moves through the collection chamber 20, vaporized water is condensed out, and collects with the desiccant 30 in the bottom portion 34 of the chamber 20. The desiccant 30 is diluted as it adsorbs or absorbs the water from the first airflow 28. Although the desiccant 30 shown in FIG. 2 is liquid, the present invention contemplates the use of solid desiccants, or dual phase desiccants-e.g., solid and liquid. Any desiccant material effective to produce the desired result may be used, including solids, liquids, solutions, aqueous solutions, mixtures, and combinations thereof. Lithium chloride (LiCl) and calcium chloride (CaCl2) are typical of liquid desiccant solutions, but other liquid desiccants may be employed.

[0029] Liquid desiccants such as polycols, alone or in mixture, may be used. Typical polycols include liquid compounds such as ethylene glycol, propylene glycol, butylene glycol, pentylene glycol, glycerol, trimethyol propane, diethytlene glycol, triethylene glycol, tetraethylene glycol, dipropylene glycol, tripropylene glycol, tetrapropylene glycol, and mixtures thereof. Polyol compounds which are normally solid, but which are substantially soluble in anhydrous liquid polyols or liquid hydroxyl amines, may also be used. Typical of these solid polyol compounds are erythritol, sorbitol, pentaerythritol and low molecular weight sugars. Typical hydroxyl amines include alkanolamines, such as monoethanol amine, diethanol amine, triethanol amine, isopropanol amine, including mono, di, and tri, isopropanol amine or digylcolamine.

Related: Create Safe Drinking Water

[0030] Still other types of desiccants such as montmorillonite clay, silica gel, molecular sieves, CaO, CaSO4 can all be used. As would be evident to persons of ordinary skill in the art, the selection of a desirable desiccant depends, among other parameters, upon the temperature and humidity ranges of ambient air from which moisture is to be absorbed. Still other exemplary desiccants comprise materials such as P2O5, BaO, Al2O3, NaOH sticks, KOH fused, CaBr2, ZnCl2, Ba(ClO4)2, ZnBr2.

[0031] As noted above, the desiccant 30 is a liquid desiccant, which may comprise an aqueous solution of 40% lithium chloride. The desiccant 30 is pumped into the conduit 32 by a pump 36. The pump 36 pumps the desiccant 30 through a first heat exchanger 38 prior to its introduction into the collection chamber 20. By cooling the desiccant 30, its ability to remove water from the first airflow 28 is increased. A fluid, such as a refrigerant, is passed through the heat exchanger 38 via conduits 40, 42. The desiccant 30 is cooled in the heat exchanger 38 to a temperature below that of the first airflow 28. In this way, the airflow 28 is cooled as it passes through the collection chamber 20. As an alternative to the heat exchanger 38, a heat exchanger may be placed inside the collection chamber 20 to cool the first airflow 28 directly, or to cool the desiccant 30 after it is sprayed into the collection chamber 20.

[0032] The regeneration chamber 22 also includes an inlet 44 and an outlet 46, which facilitate movement of a second airflow 48 into and out of the regeneration chamber 22. In the embodiment shown in FIG. 1, the two chambers 20, 22 are conveniently disposed adjacent each other inside a housing 50. Between the two chambers 20, 22 is a partition 52, which allows the hydrous desiccant from the collection chamber 20 to mix with desiccant in the regeneration chamber 22, and vice versa. Instead of the partition 52, a valve or other flow control device may be used to control the flow of desiccant between the two chambers 20, 22. In the embodiment shown in FIG. 2, the partition 52 allows for equalization in concentration of the desiccant 30 which is achieved through osmotic flow. Thus, the desiccant 30 in the collection chamber 20 is not rapidly diluted and rendered ineffective. In addition, a float (not shown) may be employed to operate in an opening 54 just below the partition 52. The float can be used to help measure the temperature differential between the two chambers 20, 22, and to control the degree of sensible heat transfer. By modifying the size of the opening 54, via a float or some other structure, it is possible to influence the degree of sensible heat transfer and further optimize the system 10.

Related: The Fluoridated Water Conspiracy: Unveiling the Potential Risks

[0033] As with the collection chamber 20, the regeneration chamber 22 also includes a pump 56 which is used to pump the desiccant 30 into the regeneration chamber 22 through a conduit 58. The desiccant 30 is sprayed into the regeneration chamber 22 with an orientation that is generally perpendicular to at least a portion of the second airflow 48. This is similar to the arrangement in the collection chamber 20. By crossing the flow directions between the desiccant 30 and the first and second airflows 28, 48, contact between the air and the desiccant is increased, without generating the high pressure that might be associated with parallel flows.

[0034] As shown in FIG. 2, the desiccant 30 is pumped by the pump 56 through a second heat exchanger 60. Heat can be added to the heat exchanger 60 from any convenient source, via conduits 62, 64. By passing through the heat exchanger 60, the desiccant 30 is heated to a temperature above the temperature of the second airflow 48, so that the second airflow 48 is heated as it passes through the regeneration chamber 22. By heating the second airflow 48, more water is evaporated from the desiccant 30 into the second airflow 48. As an alternative to the heat exchanger 60, which is located outside the regeneration chamber 22, a heat exchanger 66, shown in phantom in FIG. 2, may be located inside the regeneration chamber 22. The heat exchanger 66 can be supplied with heat from any convenient source via conduits 68, 70.

[0035] In alternative embodiments, non-liquid desiccants can be used in a variety of configurations. In one example, a solid water absorbing material is used to absorb water from an incoming air stream and then subjected to a dry air stream that causes the transfer of water vapor from the solid water absorbing material to the dry air stream. The transfer may occur through a series of alternating cycling air streams, each of which may be warmed or cooled depending on what would best cause the transfer of water vapor. In another example, solid desiccants can be dispersed into an air trap that contacts incoming air streams. The desiccants absorb or adsorb water from the air. The trap is then exposed to a heating element, thereby causing the water to evaporate from the desiccant and regenerating the desiccant. The air containing the evaporated water is then exposed to a water extraction stage, as described below.

[0036] The humid air manufacturing stage 12 results in two separate airflows exiting the chambers 20, 22. The first airflow 28 of now dry air exits the collection chamber 20 through the outlet 26, and the second airflow 48 of now humid air exits the regeneration chamber 22 through the outlet 46. The water extraction stage 14 includes a system heat exchanger 72. In the embodiment shown in FIG. 2, the heat exchanger 72 is configured to receive the cool dry airflow 28 and the warm humid airflow 48, such that heat is transferred between the two airflows 28, 48. In particular, heat will be transferred from the warmer airflow 48 to the cooler airflow 28, resulting in extraction of water 74 from the second airflow 48. As an alternative to using the first airflow 28 to cool the second airflow 48, another source of cooling, such as a refrigerant, may be passed through the heat exchanger 72 via conduits 76, 78.

[0037] One of ordinary skill in the art would appreciate that the extraction of water from the first airflow 28 increases the latent heat of the desiccant 30, and results in latent cooling of the first airflow 28. Additionally, because the desiccant 30 (or alternatively the chamber 20, or both) is cooled, the first airflow 28 itself undergoes sensible cooling that lowers its temperature level, thereby creating cooled, dry air. In one embodiment, the present invention uses 10 liters of lithium chloride solution to extract 2 liters per hour of moisture from incoming air that is provided by an air blower rated at 250 m<3> /hour. The result is a sensible cooling capacity of 0.7 kW and a latent cooling capacity of 1.4 kW, thereby enabling a temperature reduction in the air of 8.4[deg.] C.

Related: Water From The Air - More Precious Than Oil!

[0038] As shown in FIG. 3, the first and second airflows 28, 48 are pulled through the heat exchanger 72 (and respectively through the chambers 20, 22) by a fan 80. The heat exchanger 72 is a radiator-type heat exchanger which includes a plurality of air tubes 82 through which the airflow 48 passes. As heat is transferred from the airflow 48 to the airflow 28, water 74 condenses out of the airflow 48 and trickles down a header pipe 84. The water 74 actuates a float valve 86 which may be configured to work by its own buoyant power or by a sensor. The water 74 then drops into a condensate collector 88 after being released by the float valve 86.

[0039] Once the water is extracted from the airflow 48 and collected in the condensate collector 88, it can be subject to a variety of filtration, purification, storage, and dispensing steps. As shown in FIG. 3, the water leaving the heat exchanger 72 is then processed by a water treatment subsystem 89 at the water purification and filtration stage 16 and dispensed the water dispensing stage 18. The additional steps actually employed in these last two stages 16, 18 are dependent upon the type and nature of the application for which the water producing system 10 is being used. For example, in one embodiment, the water purification and filtration stage 16 uses ceramic filters to remove water born pathogens. In addition, the ceramic filters can be filled with a high-grade silver activated carbon.

[0040] Various grades of readily available activated carbons, such as Columbia, Pittsburgh, Barnebey-Cheney, Continental, Bone Char, Acticarbone, Cochranex, Carboraffin, by way of illustration and not limitation, can be used as the medium. Such carbons can be prepared from a variety of sources such as wood, bones, blood, carbohydrates, coal, coconut shells, corncobs and cornstalks, kelp, lignite, nutshells, oil shale, petroleum coke, rubber waste and sawdust. The activated carbon employed may be in various forms, for example it may be in granular, powdered or pelleted form or combined in preformed materials such as fibers, slurry, paper or other supporting media. Because of a high adsorption rate, granular carbons may be particularly effective. A mesh size of less than about 100 may be more effective than larger sizes, but larger sizes may be suitable where higher flow rates are desired.

[0041] In yet another alternative embodiment, a kinetic degradation fluxion (KDF) and carbon combination filter is used. This is similar to a granular activated carbon filter with additional metal removal capabilities, including lead. Chlorine is converted to chloride by the KDF portion, which is a zinc/copper composite. This extends the life of the carbon media bed. This type of filtration also helps to minimize biological activity. Additionally and/or alternatively, the present invention uses reverse osmosis, ion exchange demineralization, and/or ultra fine membrane filters as stand alone or in combinations.

[0042] Another embodiment of the present invention utilizes fabric filters having enhanced capabilities for removing contaminants from a fluid. The fabric filters utilized may be treated with an inorganic hydrolyzing composition such as sodium hydroxide. Such a filtration system, utilizing a cellulose acetate fiber filter, effectively removes microbiological flora. By utilizing such a system in conjunction with a virus filtration unit and a reverse osmosis membrane, a liquid such as water may be very highly purified. Media such as activated carbon, which are used for adsorbing viruses, are treated with inorganic sodium containing hydrolyzing composition.

[0043] It may be desirable, however, to use a filtration system that is easily maintained, where the filters can be regenerated, and where the filters can be used without requiring frequent replacements. Additionally, numerous other filters can be used at different stages in the process, including UV filters, sediment filters, pre-carbon filters, post-carbon filters, and ultrafiltration cartridges.

[0044] Referring back to FIG. 3, one embodiment of the present invention includes an ultraviolet light unit 90. The UV light unit 90 can be advantageously combined with a plurality of other filters to improve the quality of water. The UV unit 90 is designed so as to maximize the bacteria-killing effect of an optimal frequency of ultraviolet radiation. Accordingly, the interior surfaces of the unit 90 are coated with reflective material, and the unit 90 is shaped around a high-intensity, short wavelength ultraviolet lamp (not shown) so as to direct the liquid condensate into the optimum zone of bacteria destruction. The UV lamp may be changed by removal of the unit cap 92.

[0045] A pump 94, preferably self-priming, is activated according to the volume of water within the UV unit 90 by means of a lower sensor 96 and an upper sensor 98. The lower sensor 96 and upper sensor 98 are both electrically connected to a pump relay switch (not shown) that closes and allows power to the pump 94 when both the lower sensor 96 and the upper sensor 98 are immersed in water. The pump 94 provides pressure sufficient to pull water from the second end 99 of the UV unit 90, forcing water through a solid-core charcoal filter 100 and a mineralizing cartridge 102 into a storage tank system 104. The pump 94, solid-core charcoal filter 100, mineralizing cartridge 102 for adding minerals to the purified water, and the storage tank 104 fluidly communicate via a conduit 106. A check valve 108, placed serially with respect to the pump 94 and UV unit 90, prevents reversal of water flow when the pump 94 is deactivated.

[0046] To regulate the level of water in the storage tank 104, the cover of the storage tank 104 is provided with an overflow float switch that regulates the speed of, or disallows power to, the multi-speed fan 80, thereby stopping and/or reducing the rate of condensation at the dew-forming surfaces of the heat exchanger 72 when the water level reaches the cover of the tank 104. In an alternate embodiment, where a heat exchanger, such as the heat exchanger 72, is cooled using typical refrigerant-expansion coils, power may be switched off to the refrigerant compressor (not shown) when the level of the water in the storage tank 104 approaches the attached storage tank cover, thereby stopping water condensation.

[0047] In the embodiment shown in FIG. 3, the liquid condensate is additionally passed through an oxygenator 110 prior to introduction into the storage tank 104, in order to healthfully introduce oxygen into the water. This completes an initial, or first treatment of the water, which, as explained below, may be subject to a second and subsequent treatments by recirculation through at least a portion of the water treatment subsystem 89. A quick-disconnect tube 112 may additionally be attached to direct water from the storage tank 104into external containers. In one embodiment these external containers are large cisterns to store water for industrial, agricultural or commercial consumption. The water collected in the external containers can be further treated through chemical disinfectants such as chlorine, bromine, iodine, potassium permanganate, cooper and silver ions, alkalis, acids and ozone or any other suitable chemical agent known to persons of ordinary skill in the art.

[0048] To make the system 10 more desirable for office or home use, the system 10 is optionally fitted with subsystems for producing water at three temperatures-i.e., hot, cold and ambient. In one embodiment, water from the storage tank 104 is allowed to gravity feed through a self-sealing gasket and through a tube 114 into a cold-water tank system 116. The water may then be chilled within the cold-water tank system 116 by a low-pressure evaporator refrigerant coil of a secondary heat absorber (not shown). Other heat absorber methods may alternatively be used to cool the water, such as Peltier-effect or chemical/magnetic cooling or any other effective method. The water may be further gravity dispensed outside by means of a spigot (not shown). Energy dissipation from cold-water tank 116 is decreased by insulation. Additionally, a securable tube 118 may be sealing connected to the cold-water tank 116 to permit direct introduction of medicines and/or vitamins into the cold-water tank 116.

[0049] Water from the cold-water tank 116 further flows by gravity into a hot water tank system 120. The water may then be heated within the hot water tank system 120 by a heating element 122. The water is dispensed by means of another childproof spigot (not shown). The temperature of both hot and cold water is optionally displayed on a display panel. In one embodiment, ambient temperature water is dispensed from the hot water tank 120 via a spigot (not shown) when the heating element 122 is not provided with electrical power. In an alternate embodiment, ambient temperature water is dispensed directly from the storage tank 104 via a separate spigot (not shown).

[0050] To maintain its purity and freshness, water in the storage tank 104 may be recirculated on a periodic basis through at least some of the water treatment subsystem 89. For example, water from the tank 104 may be recirculated through the UV unit 90; however, in the embodiment shown in FIG. 3, the water is only recirculated through the filter 100, the mineralizer 102, and the oxygenator 110. A solenoid valve 124, placed serially in fluid communication via conduit 126 between the storage tank 104 and the UV unit 90, prevents flow of water from the storage tank 104 to the UV unit 90 unless electrical power is supplied to the solenoid valve 124. This prevents water in the storage tank 104 from draining if electrical power to the apparatus fails. Recirculation of the condensate is accomplished by activating a recirculation pump (not shown) at predetermined time intervals. By this repeated process, water is intermittently and continually recirculated across portions of the water treatment subsystem 89 whenever the water producing system 10 is in use. The flow duration may be defined by the volume circulated or by time. An indicator port (not shown) on the exterior of the UV unit 90 may be used to confirm proper operation of the UV unit 90.

[0051] In one embodiment, water can be collected from any or all of the tanks 104, 116 and/or 120 in an external container (not shown) wherein cartridges of medicines and/or vitamins can be advantageously inserted. This arrangement keeps the medicated-vitamin-supplemented water mass from being recirculated through the UV bacteriostat zone.

[0052] In the embodiment shown in FIG. 3, an external, secondary source of water 128, such a municipal water supply, supplies water to the storage tank 104 in the event of low water level in the tank 104. Accordingly, conduit 106 is fitted with a tee 130 to permit fluid communication with the external water source 128. A solenoid valve 132 is provided to prevent water from flowing through the external water source side of the tee 130 unless activated by an actuating electric power signal. At the external water source side of the solenoid valve 132, a female quick-disconnect fitting (not shown) is provided to permit easy coupling and uncoupling of external water source 128. The externally supplied water is passed through the tee 130 in the direction of the storage tank 104. A check valve (not shown) can be used to prevent water from flowing toward the UV unit 90.

[0053] The externally supplied water may be directed through a reverse-osmosis membrane filter 134, which in turn, simultaneously directs filtered water into storage tank 104 and wastewater through drain outlet into a drain for disposal (not shown). A solenoid valve 136 prevents external water from entering the membrane filter 134, unless activated by electrical signals from a low water sensor 138 provided at the inside bottom of the storage tank 104. If there is low water in the storage tank 104, an electrical signal is either sent to the pump 94, or if the apparatus is connected to an external water source such as the water source 128, the signal is sent to the inlet water solenoid 136 to open it, thereby letting water pressurize the system. Optionally, a booster pump 140 is provided at the external water source end of the solenoid valve 136 to pump pressurized external water through a fluidly communicating sand/sediment filter and pre-filter 142, serially provided between the booster pump 140 and membrane filter 134, to remove heavy metals and VOC's from the external water.

Scientists Have Created a Device That Sucks Water Out of Thin Air, Even in the Desert:

✔ It’s the only proven, EXCLUSIVE step-by-step guide showing you EXACTLY how to create your own “home oasis” TODAY…and how to survive any tough century long drought…

✔ It was providing a steady, robust supply of fresh, pure water ON DEMAND…

★ Use free electricity for Water generator from the Air: Free Electricity and Water Solutions